Combination Tools

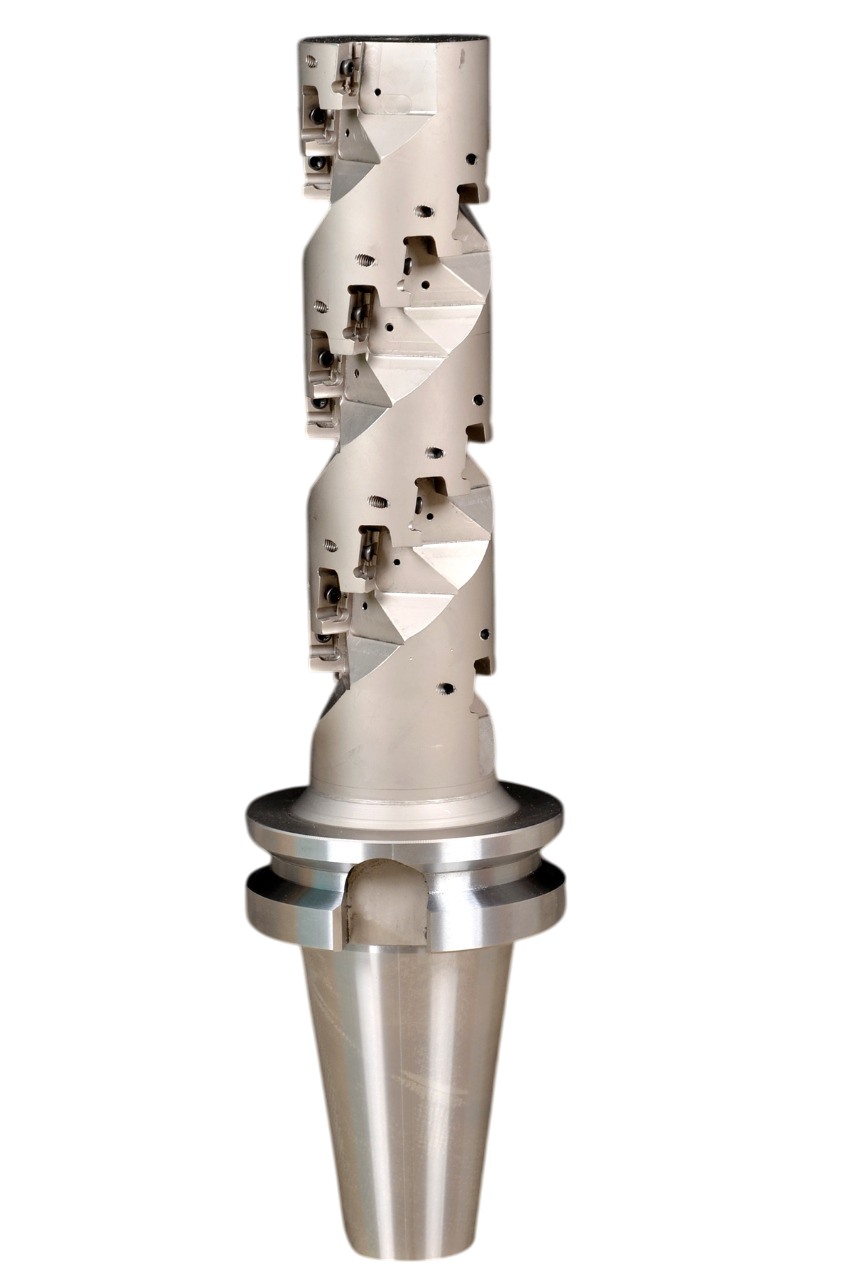

Combination Boring Bars

Boring Tool Holders and how they are secured using different types of clamping mechanisms. Boring holders are used to enlarge or finish holes in a workpiece, and they must hold boring bars rigidly during cutting

Our Standard tooling’s are:

- Roughing Boring Bars With Integrated clamping tapers like BT, ISO, SK, CAT, HSK etc.

- Finishing Boring Bars with Micro Boring units of any make integrated with different clamping Tapers.

- Special boring Bars for Valve seat machining with angle adjustment cartridges and detachable reamers.

- OD turning tools for VMC’s

- Dampened Boring bars with carbide rods and pads. For machining bores with high L/D ratios.

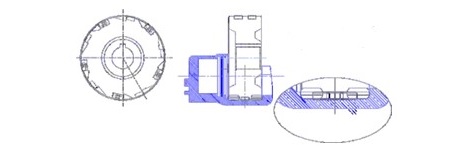

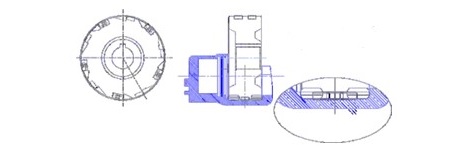

Special Trepaning cum Grooving Tool

Has a center pilot that fits into pre-drilled holes, ensuring

precise alignment and flat surface cutting around the hole.

Has a center pilot that fits into pre-drilled holes, ensuring

precise alignment and flat surface cutting around the hole.

Has a center pilot that fits into pre-drilled holes, ensuring

precise alignment and flat surface cutting around the hole.

Special Slot Milling

Cutter

Combines spot facing and counterboring; creates a flat seat and a

larger recess for bolt heads or socket caps.

Combines spot facing and counterboring; creates a flat seat and a

larger recess for bolt heads or socket caps.

Combines spot facing and counterboring; creates a flat seat and a

larger recess for bolt heads or socket caps.

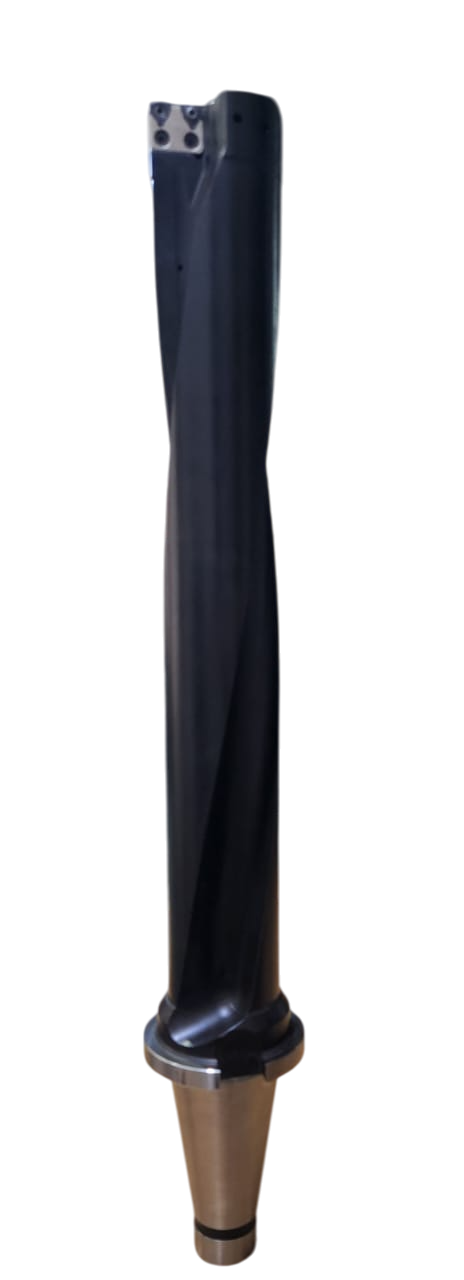

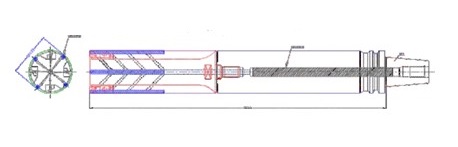

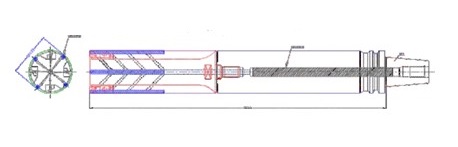

Special Rough Boring Bar

Allows changing pilot diameters to match various hole sizes,

offering flexibility for multi-size spot facing with one cutter.

Allows changing pilot diameters to match various hole sizes,

offering flexibility for multi-size spot facing with one cutter.

Allows changing pilot diameters to match various hole sizes,

offering flexibility for multi-size spot facing with one cutter.

Special Profile

Milling

Uses indexable carbide inserts for high-speed, durable cutting—ideal

for CNC machines and mass production applications.

Uses indexable carbide inserts for high-speed, durable cutting—ideal

for CNC machines and mass production applications.

Uses indexable carbide inserts for high-speed, durable cutting—ideal

for CNC machines and mass production applications.